The process of making poly bags

Quality… Service… Value…

We manufacture custom poly bags

Swastik Packaging manufactures poly bags using blown film extrusion. Our bag machines seal and cut bags to each client’s specifications once the plastic has been formed and wound on a roll.

Here’s what it really takes to make polybags.

Step 1 -

The Blown-Film Extrusion Process

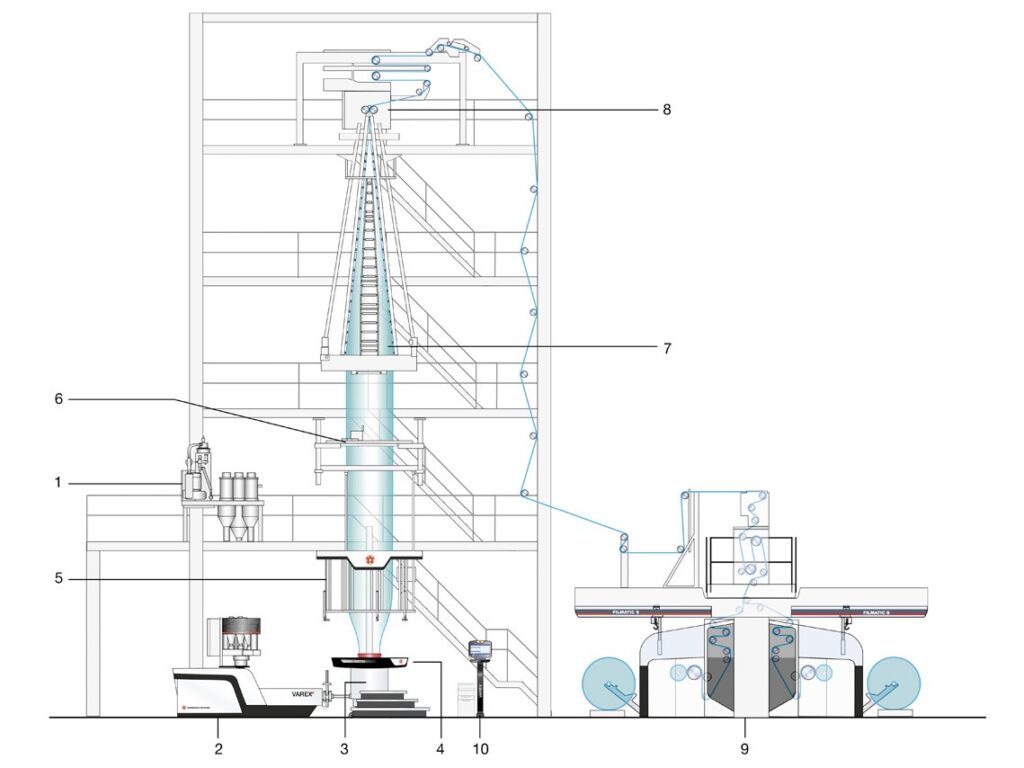

Blown-film extrusion is the first step in making poly bags. When using this process, the following occurs:

- In order to become pliable, plastic pellets (called resins) are first meltedunder controlled conditions.

- The resin pellets are extruded through a Round die gap to create a Long Bubble of plastic. When the Bubble is in this molten state, it is pried off at one end, then inflated and stretched to the desired diameter and thickness.

- Plasticbubbles are inflated vertically up a tower before they are rolled up, leaving them to cool before they are flattened out.

- As soon as the plastic is on a roll, it can be cut into tubing, single-wound sheeting, or centerfold sheeting. The plastic is usually transformed into poly bags.

Diagram of the extrusion process

Plastic pellets (resin)

Step 2 -

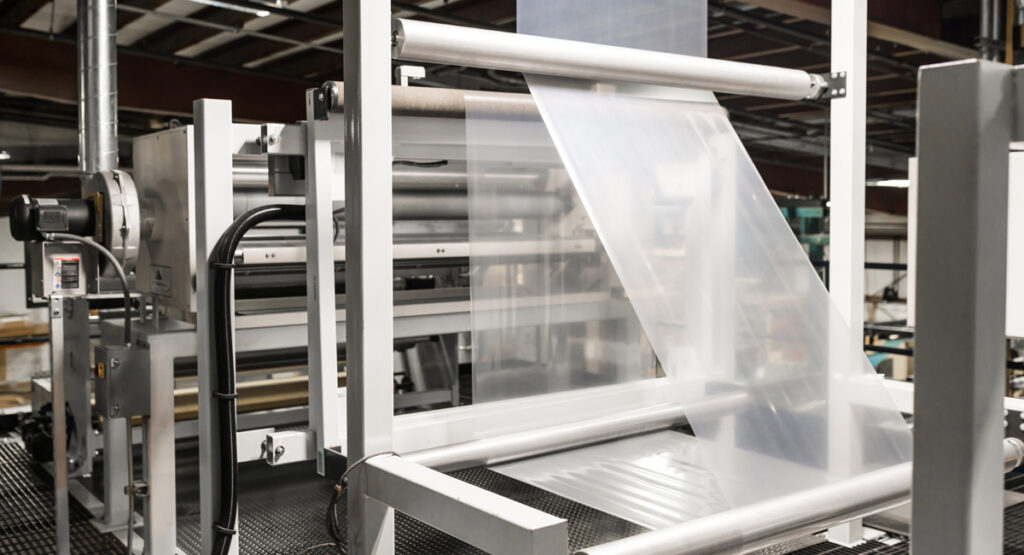

Making Poly Bags from Plastic Rolls

In the process of converting blown-film plastic rolls into poly bags, we do as follows:

- Initially, rolls of plastic tubing or sheeting are fed through a machine that cuts the material to the proper length.

- The material is then sealed with a seal of the correct length and cut off to make an individual bag.

- Afterward, we repeat this process until we have all the poly bags an order requires.

Frequently Asked Questions

You can find answers in our list of frequently asked questions. If You Need More Help then Write to us on our email

A variety of factors play a role in manufacturing. Depending on the size of the poly bags we're making, we can produce up to 80,000 bags per hour.

Our production capacity may be only 3,000 bags an hour if we manufacture larger bags.

The speed of poly bag production is variable based on bag thickness and size, but generally speaking, the process is fast.

In order to produce high-quality film for polybags, you need great equipment. If a machine is capable of maintaining a constant flow of material during the process, the product will be more consistent, even, and quality-controlled.

As part of Swastik Manufacturing, we have modern poly bag manufacturing machines with servo drive motors. This ensures that the bag quality is exceptional, which is what makes a Swastik bag distinctive.

Your Trusted Poly Bag & Film Manufacturer

How To Choose the Right Poly Bag to Fit Your Needs

You should clearly identify the purpose that the bag will be intended for. You don’t want the bag to be flimsy and break apart when heavy items are put into it. The extra cost of better bags is worth the cost as double bagging is not going to save you money.

Not sure where to start? We're here to help !

There's a lot to consider when it comes to ordering poly bags, plastic liners, or rolls of film. The Swastik team is here for you. Let us know what you're looking for, and we'll help you determine which poly bag and plastic product options are best for your application.